Roofs

Copper roof - TECMA building, Alzira (caption) IntroductionHere we will briefly look at the possibilities for constructing the roof and the possible systems. All Quinta Metálica® roofs are built by installing several layers of different materials on top of each other, where each layer has its own particular function. If we start from the outside, moving inwards, we have the following generic layers.

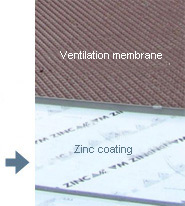

Layers in detailSeparator sheet / ventilation membrane

This membrane makes it easier for the panelling to dilate (in response to thermal changes) because it provides a surface over which the metal can easily slide. On complicated roofs it also acts as a second waterproofing barrier. For copper, stainless steel and titanium roofs, Quinta Metálica usually uses breathable membranes because they provide both functions effectively and they also help to protect the roof against condensation, trapping the water between it and the inside of the metal, until it drains down towards the gutter or evaporates. For zinc and lead roofs, Quinta Metálica always installs a ventilation membrane because it lets the inside of the metal breathe, preventing the condensed water from making contact with the zinc, prolonging the metal's useful life. Direct supportOur most used frequently systems to cover a metal roof - the seam and the bar joint - are made with thin metal plates and therefore require direct support (the support immediately below the metal) stretching over the whole metal surface. This support withstands all forces and makes it perfectly possible to cross the roofs. The support has to be reasonably smooth and regular, as any appreciable defect will be transmitted through the panelling and will be visible. The types most used by Quinta Metálica are listed below.

Not all support materials are suitable for each metal - see the pages for each metal to obtain a list of correct materials.

Zinc roof - Cycling stadium, Berriz (caption) Thermal insulationNeither the type of insulation chosen for the roof nor its thickness has any influence on the panelling. Only in the case that the insulation provides the direct support for the metal must it meet specific requirements - it must withstand the weight of people fitting the metal without bending and it must withstand 80ºC temperatures without being damaged. UpThermal design - ventilated and non ventilated roofThe layers described above can be interspersed to give two types of roof - the ventilated roof and the non ventilated roof. Quinta Metálica makes both versions. Metal roofs and condensation

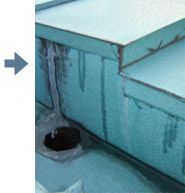

Condensation coming out from below the copper sheets and draining into a trough - symptomatic of a roof with serious condensation problems. The basic problem for a metal roof is that we have a vapour barrier exactly where we don't want it - on the cold side of the roof. If we do not design the roof carefully, it can produce significant quantities of condensation that will damage the building and its contents. This is particularly important when the humidity inside the building is high - swimming pools, gymnasiums, kitchens, etc. or the building is located in an area with very cold winters. To prevent this happening, Quinta Metálica provides two different solutions: the ventilated roof and the non ventilated roof. The ventilated roofThis solution protects the roof from condensation by carrying the damp air (from inside the building) outside by means of a moving air sheet. This air sheet runs over the top of the insulation (between the insulation and the direct support for the panelling) and lies continuously from its air intake in the eaves to its outlet on the ridgepole (or ridge). In Spain there are no rules to restrict the size of this chamber but based on our own experience and the rules in other countries, we recommend a chamber height of between 20 and 50mm. Normally the higher the sheet, the better the ventilation, although we do not recommend thicknesses over 60mm, when the air flow changes from sheet type to turbulent type, reducing its capacity. Contact Quinta Metálica for more information.

Air inlet in the eaves of a ventilated roof - Copper Building, Villarreal, Castellón This sheet can be made using structural elements (beams, cables, bars, etc.) that have a height equivalent to the thickness of the thermal insulation required, plus an additional 20 to 50mm for the chamber. The technicalities that Quinta Metálica uses make sure that the air inlet in the eaves and the outlet on the ridge are large enough to generate appropriate ventilation. For further protection against condensation, we recommend fitting a membrane below the thermal insulation to reduce the quantity of damp air that the air sheet has to dissipate. Which solution should we apply?Ventilated roofs work well in Spain with all metals. This is compulsory when we are panelling with zinc or lead. It is suitable for roofs with one gable, two gables, roofs composed of flat surfaces, with good slopes. However, when the shape of the roof is complicated, with many changes in slope, or simply the roof gables do not have much slope at all, managing to build an air chamber that works well is not easy and in these circumstances a non ventilated roof with its vapour barrier will work better. To get technical evaluation for your project roof's thermal design, please contact Quinta Metálica, and we will be happy to help you to design your roof properly. The non ventilated roofThis solution protects the roof from condensation by fitting a vapour barrier below the thermal insulation. This barrier has the function of eliminating the possibility of filtrations of damp air from inside the building through the insulation towards the cold parts of the roof and condensing. Its correct operation is fundamental so in our opinion it is important that it has a continuous support making it easier to fit and sealing its joints perfectly. In this roof solution, there is no air chamber. Examples of building roofs

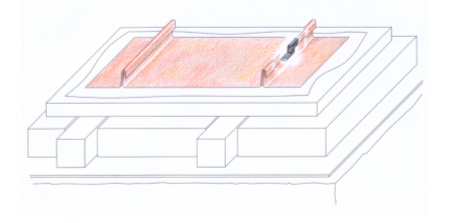

Non ventilated roof with seam on breathable plate on rigid insulation on vapour barrier:

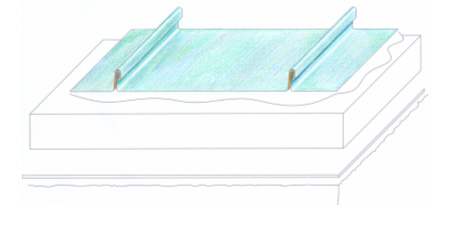

Ventilated roof with seam on ventilation membrane on board with insulation panels, insulation between omegas:

Non ventilated roof with seam on breathable lamina on board with bars, insulation between bars: Metal panelling

The systems that we use on roofs are seams and bar joints for 'hard' metals and the clamping system for lead roofs. The seam system, due to its economics, aesthetic cleaning and flexibility is, far and away, the most used by Quinta Metálica. For more details on the systems themselves, please refer to our files on each of them. Independently of the covering system, the installation starts at the lower part of the roof, fitting guttering and fastening strips. Here we pay special attention to aligning these elements correctly as the roof plates hook on to them giving the lower contour of the roof. If the roof has a gutter, the brackets are fixed before the guttering and if it has a front, this is fastened down before fixing the brackets. The fastening strips or side pieces required to install the lateral finish on the roof are fastened next. The roof plates can now to be fitted. We make sure that they are correctly aligned and positioned in accordance with the roof disassembly drawing. The installation goes from left to right or right to left, or in both directions if we start with a central plate. The plates are fastened by occasionally crimping them. We prepare the folds to form the foot and the head of the plates, in the eaves and on the ridge (or hip) respectively. At the foot we make sure that a space has been left for dilation between the plate and the guttering. Both for the plate foot and its head, we use different solutions depending on the technical needs (slope, ventilation, etc.) and aesthetic requirements mentioned before with the Ministry for Public Works or the builder. We then finish the roof by installing the ridge and hip covers, and forming finishes against walls, chimneys, gas outlets and other elements opening out on to the roof. Finally, we finish crimping the plates together along their whole length.

Throughout this whole process we try to make sure that:

We take it for granted that the roof will be waterproof and will protect the building for decades from everything the weather has to throw at it.

El Torcal de Antequera Nature Park Visitors' Centre, Málaga. Natural zinc roof (caption) Request for information

For technical consultancy on your project, please contact Quinta Metálica and we will be happy to help you

Up Representative works Biblioteca del Estado en Ciudad Real

Ciudad Real Biblioteca del Estado en Ciudad Real

Ciudad Real

Reforma y ampliación del Edificio Kultur Etxea. Berriz

Berriz. Vizcaya Reforma y ampliación del Edificio Kultur Etxea. Berriz

Berriz. Vizcaya

Edificio de viviendas en Llanes

Llanes. Asturias Edificio de viviendas en Llanes

Llanes. Asturias

Edificio La Huertona

Santander. Cantabria Edificio La Huertona

Santander. Cantabria

Viviendas Edificio Cobre

Villareal. Castellón Viviendas Edificio Cobre

Villareal. Castellón

Edificio de 21 viviendas Luz de Jávea

Cruce Avda del Pla con C/Vicenza - Jávea. Alicante Edificio de 21 viviendas Luz de Jávea

Cruce Avda del Pla con C/Vicenza - Jávea. Alicante

Antiguo Hospicio Maudes - Rehabilitación Biblioteca

Calle Maudes, Madrid Antiguo Hospicio Maudes - Rehabilitación Biblioteca

Calle Maudes, Madrid

Centro de Visitantes del Parque Natural El Torcal

Antequera. Málaga Centro de Visitantes del Parque Natural El Torcal

Antequera. Málaga

Museo del Vino de Almendralejo

Almendralejo. Badajoz

Vivienda unifamiliar - Zurilla

C/ Emerenciana Zurilla, 78. Madrid Museo del Vino de Almendralejo

Almendralejo. Badajoz

Vivienda unifamiliar - Zurilla

C/ Emerenciana Zurilla, 78. Madrid

15 viviendas y garajes

Benalmádena Costa 15 viviendas y garajes

Benalmádena Costa

Edificio de 41 viviendas

El Astillero. Cantabria Edificio de 41 viviendas

El Astillero. Cantabria

Edificio de viviendas en Miribilla

Bilbao Edificio de viviendas en Miribilla

Bilbao

Velodromo de Berriz

Berriz Velodromo de Berriz

Berriz

Casa de Cultura de Aretxabaleta

C/Santa Cruz, 18 - 20550 Aretxabaleta. Guipuzcoa Casa de Cultura de Aretxabaleta

C/Santa Cruz, 18 - 20550 Aretxabaleta. Guipuzcoa

Vivienda unifamiliar en Guarda

Guarda. Portugal Vivienda unifamiliar en Guarda

Guarda. Portugal

Viviendas en Montecarmelo

Montecarmelo. Madrid Viviendas en Montecarmelo

Montecarmelo. Madrid

Centro Cultural en Fornos de Algodres

Fornos de Algodres. Portugal Centro Cultural en Fornos de Algodres

Fornos de Algodres. Portugal

Edificio Tecma

Alzira. Valencia Edificio Tecma

Alzira. Valencia

Bodega Casona Micaela

Villa Verde de Trucios. Cantabria Bodega Casona Micaela

Villa Verde de Trucios. Cantabria

Supermercado Aldi en Bormujos

Bormujos Supermercado Aldi en Bormujos

Bormujos

Viviendas en Parque Palmera

Sevilla Viviendas en Parque Palmera

Sevilla

Edificio de viviendas en Calle Córdoba

Puerta del Mar, Málaga Edificio de viviendas en Calle Córdoba

Puerta del Mar, Málaga

Vivienda Unifamiliar José Córdoba

Málaga Vivienda Unifamiliar José Córdoba

Málaga

Vivienda Unifamiliar

Málaga Vivienda Unifamiliar

Málaga

Fundación San Telmo

Málaga Fundación San Telmo

Málaga

Nueva Sede de Capitania Marítima

Sevilla Nueva Sede de Capitania Marítima

Sevilla

Piscinas en Jaca

Jaca - Huesca Piscinas en Jaca

Jaca - Huesca

Residencia las Navas del Marques

Las Navas del Marques - Avila Residencia las Navas del Marques

Las Navas del Marques - Avila

Caseta campo de Golf Saldaña

Saldaña - Burgos Caseta campo de Golf Saldaña

Saldaña - Burgos

Centro de visitantes El Torcal

Antequera - Malaga Centro de visitantes El Torcal

Antequera - Malaga

Parador de Antequera

Antequera - Malaga Parador de Antequera

Antequera - Malaga

La Laguna de Fuente la Piedra

Fuente la Piedra - Malaga La Laguna de Fuente la Piedra

Fuente la Piedra - Malaga

Silla Hotel Husa Santo Domingo

Lucena - Córdoba Silla Hotel Husa Santo Domingo

Lucena - Córdoba

Edificio Prorrodya

Sevilla Edificio Prorrodya

Sevilla

- copia.jpg) Enciso El Barranco Perdido

Enciso, La Rioja Enciso El Barranco Perdido

Enciso, La Rioja

.jpg) Pabellón Polideportivo Pobla de Lillet

Pobla de Lillet (Alt Berguedá), Barcelona Pabellón Polideportivo Pobla de Lillet

Pobla de Lillet (Alt Berguedá), Barcelona

|

© Quinta Metálica · c. Juan Bautista Escudero 273· Córdoba· 14014 Córdoba

Tel.: 91 896 1898· arquitectura@quintametalica.com

Legal Advice